Cationic polyacrylamide

Brand rainbon

Product origin henan

Delivery time 5-8days

Supply capacity 2000tons/mouth

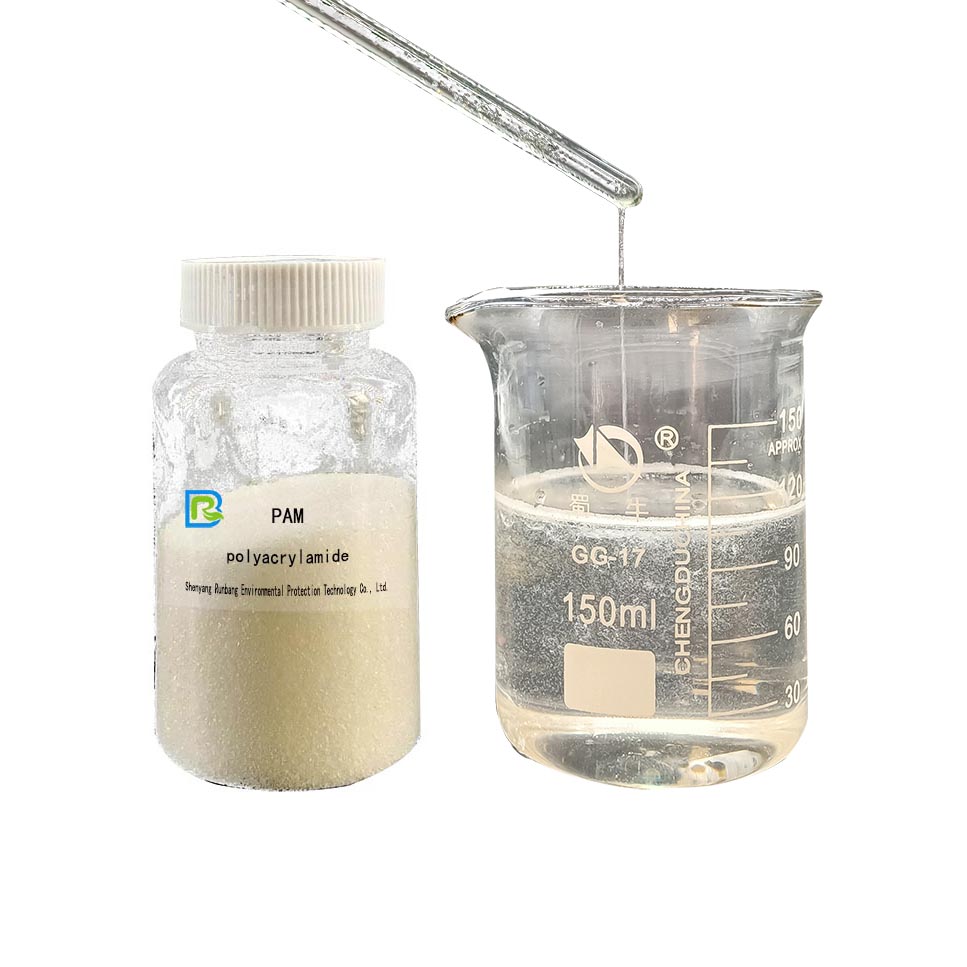

Cationic Polyacrylamide (CPAM) is formed by copolymerization of cationic monomer and acrylamide

monomer. It is a water-soluble linear polymeric flocculant. It is mainly used in flocculation and sedimentation

of sewage and sludge dewatering and so on.

Our factory mainly relies on our sales network for water treatment industry customers, with an annual production capacity of 30,000 tons of polyacrylamide production line, for different industries of water treatment process, there are mainly anionic, cationic, non-ionic three major products

Cationic polyacrylamide (CPAM) is a high-molecular-weight polymer with numerous amide and cationic groups. These groups provide strong adsorption and flocculation abilities, neutralizing the negative charges of suspended particles in water. When dissolved, CPAM forms stable flocs through electrostatic attraction, hydrogen bonding, and van der Waals forces. It is widely used in various industries

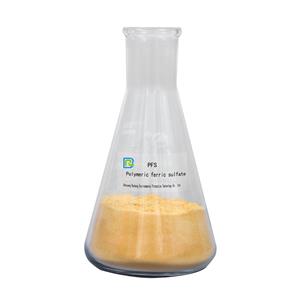

Appearance | White powder |

Solid content mass fraction% | 92.40 |

Mass fraction of acrylamide monomer(dry group)% |

0.04 |

The molecular weight million | 8million-12million |

Ion degrees% | 12-70 |

Dissolution time min | ≤60 |

Insoluble residue% | 0 12 |

The purity% | 99.5 |

40-80 |

CAS No. 9003-05-8

Product Advantages

1. Economical and effective at low dosage levels.

2. Significantly improve the sludge production efficiency or reduce the moisture content of sludge cake.

3. Promote solid liquid separation in the process of sewage treatment, thus increase the settling rate of suspended solids.

4. Highly effective in a wide PH range(2-9), capable of treating waste water and sludge under weak acidic condition.

Applications

Water Treatment:

Wastewater Treatment: CPAM is widely used in municipal and industrial wastewater treatment. Through coagulation and flocculation of pollutants, it effectively removes suspended particles and organic substances.

Sludge Dewatering: It enhances the sludge dewatering process, reducing moisture content and volume, making sludge treatment and disposal more efficient.

Paper Industry:

Retention and Drainage Aid: CPAM is used to improve the retention of fine fibers and fillers during the papermaking process, enhancing paper quality and reducing production costs.

Paper Strengthening Agent: It increases the dry and wet strength of paper, improving paper performance and durability.

Textile Industry:

Textile Dyeing and Printing: In the textile industry, CPAM is used as a sizing agent, thickener, and color-fixing agent, improving the quality and uniformity of dyed fabrics.

Petroleum Industry:

Oilfield Extraction: CPAM is used to enhance oil extraction efficiency by improving the flow and displacement performance of crude oil.

Drilling Fluid: As an additive in drilling fluids, it helps stabilize the borehole walls, reduce fluid loss,and lubricate drilling tools.

Mining:

Flotation and Sedimentation: CPAM is used in mineral processing to enhance mineral flotation :and sedimentation, improving recovery rates and concentrate quality.

Cautions

1. Non-toxic, easily soluble in water and easily moisture absorption to caking.

2. Splashes on hand and skin should be washed off with water immediately.

3. Proper storage temperature : 5'C~40'c ,should be stored in original packaging in cool and dry place

4. Premade solution of liquid polyacrylamide is not suitable for long storage. Its flocculating effect would decrease after

24 hours.

5. Low-hardness water with neutral PH range 6-9 is suggested to dissolve polyacrylamide. Using underground water and

recycled water would decrease the flocculating effect