Industrial grade poly aluminum chloride

Brand rainbon

Product origin henan

Delivery time 7-10 days

Supply capacity 4000 tons/month

Advanced water treatment coagulant. PAC offers superior purification effects. PAC effectively removes turbidity, color, and various contaminants from water. PAC is widely used in drinking water treatment, industrial wastewater treatment, paper industry, and municipal sewage treatment. As a professional PAC manufacturer with a daily production capacity of 200 tons, we offer stable, high-quality PAC supply tailored to customer needs. Our PAC is efficient, economical, and eco-friendly, making it the ideal choice for your water treatment solutions.

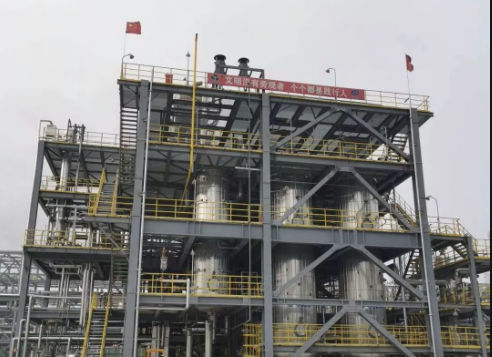

Since our establishment in 1995, our company has been at the forefront of polyaluminum chloride (PAC) production. We fully utilize local resource advantages and

collaborate with supporting industries to produce high-quality polyaluminum chloride at competitive prices. To meet the demands of different target customers and

markets for PAC, we continuously adjust our polyaluminum chloride production processes and expand our PAC manufacturing capacity.

Our advanced production facilities are now capable of producing various grades of polyaluminum chloride (PAC).

The diversification of our PAC products enables us to meet a wide range of application needs, from municipal water treatment to industrial processes where polyaluminum

chloride is essential. Our commitment to polyaluminum chloride quality, combined with decades of PAC production experience, has made us a trusted supplier of PAC

in the global water treatment chemical market.

Choose Shenyang Runbang Environmental Protection Technology Co., Ltd. for reliable, efficient, and environmentally-friendly polyaluminum chloride (PAC) solutions

tailored to your specific needs. Our expertise in PAC ensures you receive the best polyaluminum chloride products for your applications.

Poly aluminum chloride of various concentrations

Poly Aluminum Chloride -

Poly Aluminum Chloride -

≥22-26 (Industrial Grade)

① Production process:

(Calcium aluminate powder + Bauxite +

Hydrochloric acid) → Polymerization reaction

→Drum drying process

② Advantages :

Low cost, high basicity, better effect on

highly turbid wastewater

③ Disadvantages:

High impurity content

Aluninium oxide (Al2O3 )/% | Basicity/% | Appearance | Drying process |

| 22%-26% | 95-99 | Brown Granules | Drum Drying |

Poly Aluminum Chloride -

≥28 (Industrial Grade)

① Production process: (Calcium aluminate

powder+Hydrochloric acid) Polymerization

reaction→ Plate and frame filtration→Drum

drying process

② Advantages :

Latest industrial grade standard, basicity

and alumina standards are better suited for

most water qualities, granular form,

non-irritating, more user-friendly for workers

③ Disadvantages:

Granular form, slower dissolution rate

compared to powdered polyaluminum

chloride

Aluninium oxide (Al2O3 )/% | Basicity/% | Appearance | Drying process |

| ≥28% | 90-95 | Yellow Granules | Drum Drying |

Poly Aluminum Chloride - ≥28 (Industrial Grade)

① Production process:

(Calcium aluminate powder + Hydrochloric acid) Polymerization reaction → Plate and frame filtration→ Spray drying process

② Advantages :

Latest industrial grade standard, basicity and alumina standards are better suited for most water qualities, fast dissolution in powdered form

③ Disadvantages:

Spray drying process requires natural gas for drying, higher cost, powdered form is more prone to moisture absorption

Aluninium oxide (Al2O3 )/% | Basicity/% | Appearance | Drying process |

≥28% | 90-95 | Yellow Granules | Spray Drying |

Spray drying process

The process of drying liquid raw material after atomization by a centrifuge

① After drying, it is in powder form, which dissolves quickly.

Drum drying process

After the heat transfer oil inside the drum is heated, it dries the liquid polyaluminum chloride (PAC) raw material on the outer wall of the drum.

Advantages:

① The drum drying process for polyaluminum chloride (PAC) can utilize waste heat from power plants, making it a more cost-effective solution for PAC production.

② The granules of polyaluminum chloride (PAC) are less likely to disperse into the air, creating a less irritating and healthier working environment for operators involved in PAC manufacturing.

Wastewater Treatment

Suspended solids removal: PAC effectively coagulates and settles suspended particles in water.

COD reduction: Reduces Chemical Oxygen Demand through adsorption and precipitation.

Heavy metal removal: Forms insoluble metal hydroxides to remove lead, cadmium, chromium, and other heavy metal ions.

Heavy metal removal: Forms insoluble metal hydroxides to remove lead, cadmium, chromium, and other heavy metal ions.

Keywords: High-basicity PAC, Low-basicity PAC, Liquid PAC, Powder PAC

Paper Industry Wastewater Treatment

Fiber and filler removal: Coagulates fine fibers and filler particles in pulp.

Color treatment: Removes dyes and organic matter, reducing color intensity.

Recycled water treatment: Improves water reuse rate, reducing environmental pollution.

Keywords: Paper-grade PAC, High-molecular-weight PAC, Cationic PAC, Anionic PAC

Textile Dyeing Wastewater Treatment

Decolorization: Effectively removes various dyes, reducing wastewater color.

Organic matter removal: Adsorbs and precipitates organic pollutants in water.

Suspended solids removal: Coagulates fibers and particles in textile wastewater.

Keywords: Textile-grade PAC, Color-removal PAC, High-efficiency PAC

Petrochemical Wastewater Treatment

Oil-water separation: Promotes demulsification and separation of emulsified oil.

Organic matter removal: Adsorbs and precipitates petroleum- based organic compounds.

Suspended solids removal: Coagulates fine particles and suspended matter in wastewater.

Keywords: Oil-field PAC, Demulsifier PAC, High-purity PAC

Food Processing Wastewater Treatment

Protein removal: Coagulates and precipitates proteins in wastewater.

Oil and grease removal: Assists in separating oil and grease components from water.

BOD/COD reduction: Removes organic pollutants, lowering Biochemical Oxygen Demand and Chemical Oxygen Demand.

Keywords: Food-grade PAC, Low-residual PAC, Fast-settling PAC

Mining Wastewater Treatment

Heavy metal removal: Precipitates heavy metal ions in mining wastewater.

Suspended solids removal: Coagulates mineral particles and silt.

pH adjustment: Neutralizes acidic mine drainage.

Keywords: Mining-grade PAC, Acid Mine Drainage (AMD) PAC, High-alkalinity PAC

Electroplating Wastewater Treatment

Metal ion removal: Precipitates various electroplating metal ions.

Complex treatment: Breaks down metal complexes for easier metal ion removal.

pH adjustment: Neutralizes acidic and alkaline wastewater.

Keywords: Electroplating-grade PAC, Metal-complexing PAC, pH-stable PAC

Methods of using polyaluminium chloride

Polyaluminium chloride should not be used directly. It needs to be dissolved evenly in clean water and then added according to a certain ratio.

It is recommended to dissolve polyaluminium chloride by stirring for 20-40 minutes in a ratio of 5:100 of solid product to room temperature water.

When dissolving, polyaluminium chloride should be added slowly and evenly to water with stirring. The dosing port should be filtered through a grid, and the stirring speed should not be too intense.

The water temperature should preferably be maintained between 20-50℃ (room temperature is fine).

When adding the chemical solution to wastewater, adjust the dosage according to your own standards as needed.

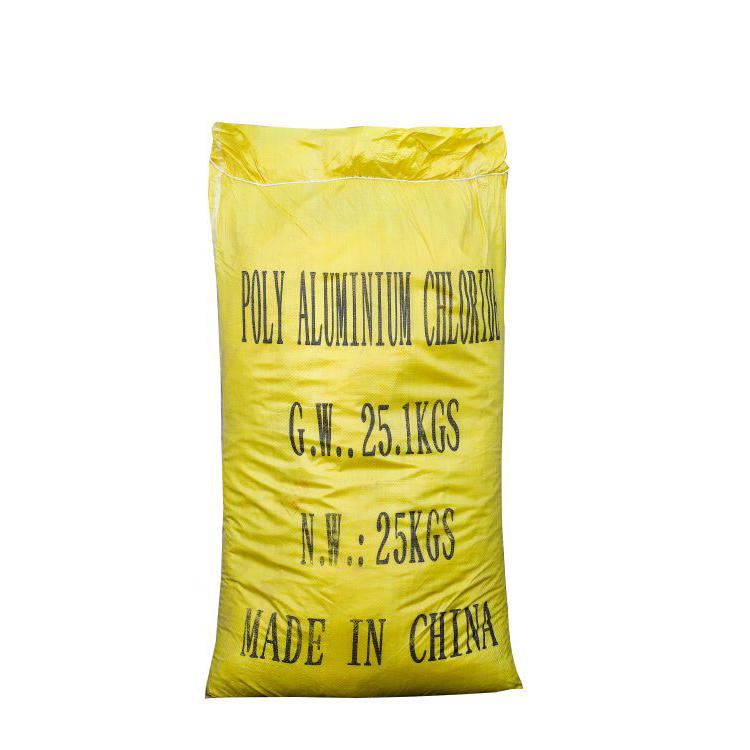

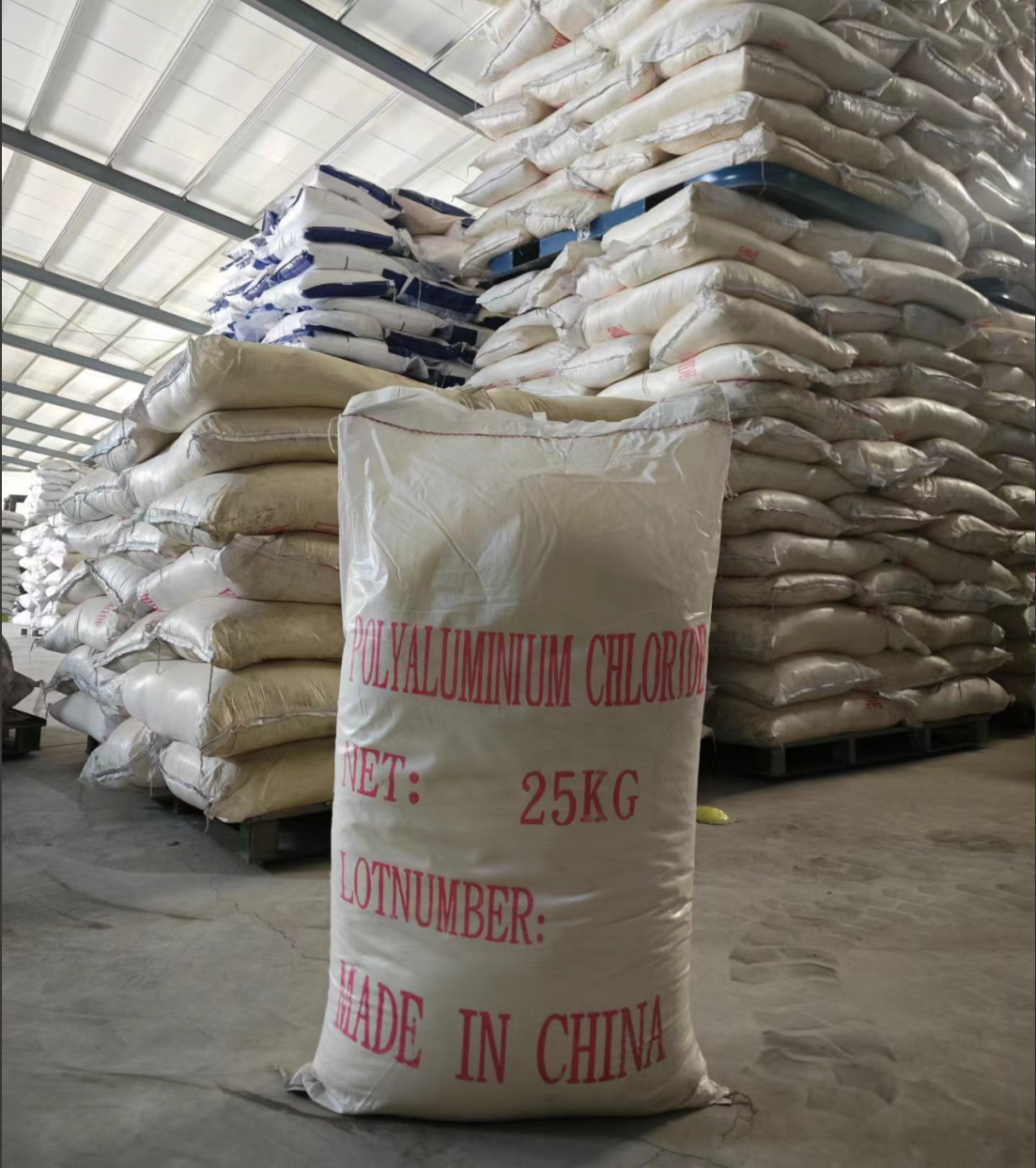

Package and Store

Factory warehouse

25 kg packaging

Comprehensive storage warehouse

1. It is harmless, non-flammable and non-explosive. It should be kept in a cool place.

2. It is packed in woven bag, 25kg per bag, also can be packed in ton bag. 3. Shelf life two years 4. Can be customized packaging

Our advantage

own factory

We are a factory with over 20 years of production experience, specializing in various types of polyaluminum chloride

Efficient supply chain

Covering warehousing and logistics at major export ports, offering cost-effective logistics solutions

24-hour service

Professional business and technical teams, providing 24-hour online service