Flocculants and Coagulant

Brand rainbon

Product origin henan

Delivery time 5-8days

Supply capacity 2000tons/mouth

Polyacrylamide (PAM) is a generic term for polymers obtained by homopolymerization of acrylamide or copolymerization with other monomers, and is one of the most widely used species of water-soluble polymers.

As polyacrylamide structural unit contains amide group, easy to form hydrogen bond, so it has good water solubility and high chemical activity, easy to graft or cross-link to get branched chain or mesh structure of a variety of modifiers, in oil extraction, water treatment, textile, paper, mineral processing, medicine, agriculture and other industries have a wide range of applications, "a hundred industry auxiliaries "known as.

The main application areas are water treatment, papermaking, mining, metallurgy, etc.; at present, the largest amount is in the field of oil extraction, and the fastest growing amount is in the field of water treatment and papermaking.

Our factory mainly relies on our sales network for water treatment industry customers, with an annual production capacity of 30,000 tons of polyacrylamide production line, for different industries of water treatment process, there are mainly anionic, cationic, non-ionic three major products

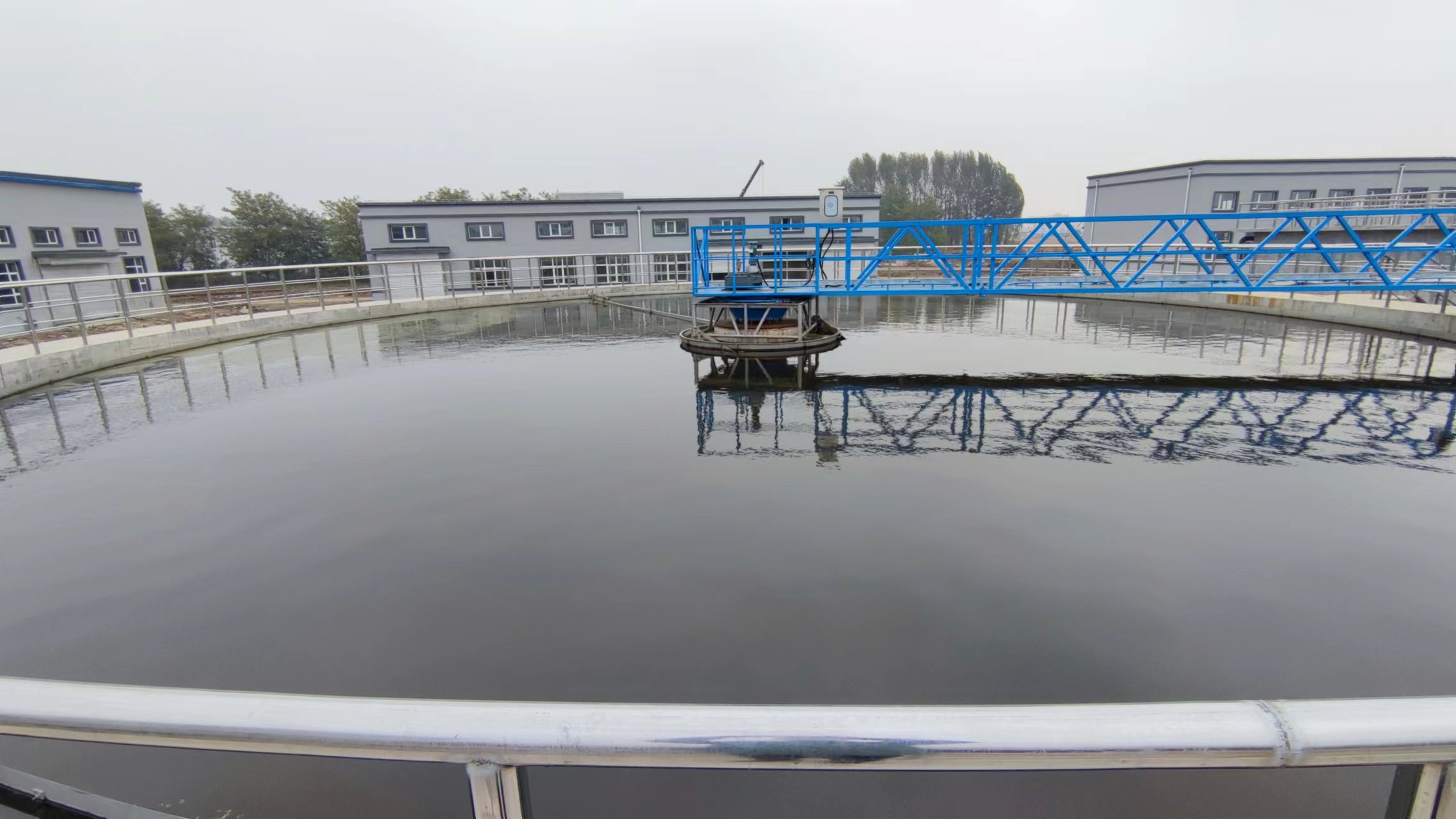

Flocculants and coagulants are named according to their role in water treatment, and polyacrylamide, as the most important flocculant and coagulant, is widely used in water treatment industry

1.Industrial wastewater

Industrial sewage exists in many industries such as papermaking, alcohol, dyeing and printing, pharmacy, electroplating, chemicals, and food and beverage. The polyacrylamides used for industrial sewage treatment depend on type and treatment process of the industrial sewage. Two main applications of polyacrylamides in industrial sewage treatment: At the front section (usually at the sedimentation tank or the floatation tank), an inorganic flocculant(such as PAC) is used with an anionic polyacryl-amide or a cationic polyacrylamide to treat industrial sewage; at the rear section, a cationic polyacrylamide (or an anionic or nonionic polyacrylamide) is used with a sludge dehydrator (usually a belt filter press, a plate-and-frame filter press, a centrifugal machine or a spiral sludge dehydrator) to press sludge.

2.Domestic sewage

Domestic sewage is wastewater generated in the daily life of people, such as the wastewater generated in toilet flushing,cooking, and bath or shower taking. It mainly comes from, residential buildings and public buildings including residences,government department buildings, schools, hospitals, stores, the toilets of public places and industrial enterprises, etc. Usually, polyacrylamides are also used for water treatment and sludge treatment in the domestic sewage. At earlier time, cationic polyacrylamides are usually used more with centrifugal machine, belt filter press, or plate-and-frame filter press in the sludge dehydration at the rear sections of domestic sewage treatment plants. As a response to the increasingly strict environmental protection policy of the state, most regions of the country need upgrading reconstruction with reference to the grade A criteria,some municipal sewage needs an in-depth treatment process in an efficient sedimentation tank if it does not meet the drainage criteria after biochemical treatment. In the in-depth treatment process, an inorganic flocculant (such as poly aluminum chloride or aluminum sulfate) and an anionic polyacrylamide are used together for flocculation and sedimentation so that the domestic sewage can meet the drainage criteria after the hazardous substances in it are reduced.

3.Mining

due to long-time mining, there are increasingly less free-mining rich ores and more and more difficult-mining lean ores instead. For difficult-mining lean ores, the conventional magnetic separation process is difficult to meet the smelting requirements. As a result, the floatation process is becoming more and more important in ore separation.

As an ore separation process making use of the physical and chemical properties of ore surfaces, it realizes ore separation,gathering and refining by making use of ore surface properties. Ores have complicated surface properties,

such as surface bond breakage, surface electrical behavior, surface ion state, surface element electronegativity,surface polarity, surface free energy, surface residual energy, surface heterogeneity, surface area, surface solubility, surface structure, and chemical compositions. These surface properties are directly related with ore floatability, so polyacrylamides can change some ore surface properties, adjust ore floatability and improve the selectivity and floatation speed in bubble mineralization. Specific type of the polyacrylamide used depends on resuit of the on-site type test.

At present, a majority of coal washeries use the wet coal preparation process.The waste and coal slime water generated in the process are both water-fine coal power mixtures mainly characterized by high turbidity, fine solid particles, universality of negative charges on solid particle surfaces, scattered status of solid particles in water because of the repulsion among like charges,and influence by gravity and Brownian movement. Due to mutual effects among the solid particle surfaces in coal slime water, the wastewater generated in coal preparation has complicated properties because it has the properties of both suspensions and colloids. At present, the mining industry in China usually uses anionic polyacrylamides for the solid-liquid separation of coal slime water because they can neutralize coal slime surfaces' electrical property and reduce their repulsion after contacting with the coal slime particles or coal slime colloids, thus realizing coagulation and sedimentation for coal slime particles.